Item NO.:

128cavPET preform molds are an essential component in the manufacturing of PET preforms, which serve as the building blocks for high-quality plastic bottles. Renowned suppliers in the industry offer a wide range of PET preform molds, incorporating advanced technology, superior design, and precise engineering. These molds are designed to meet the stringent requirements of the packaging industry, delivering exceptional performance and ensuring consistent, reliable results.

Through years of expertise and innovation, Huayan has established itself as leader in the PET preform mold market. Huayan dedicate to excellence, commitment to customer satisfaction, and continuous research and development have positioned them at the forefront of the industry.

|

(Mold Cav Qty) |

Neck Size) |

Application |

|

18 cav |

48mm, 38mm,30/25,20/25, PCO1881, PCO1810 |

Water, Juice, CSD, Daily chemical products, edible oil, medicine |

|

24 cav |

48mm,38mm,30/25,29/25, PCO1881, PCO1810 |

Water, Juice, CSD, Daily chemical, products, edible oil, medicine |

|

32 cav |

48mm,38mm,30/25,29/25, PCO1881, PCO1810 |

Water, Juice, CSD, Daily chemical products, edible oil, medicine |

|

48 cav |

48mm,38mm,30/25,29/25, PCO1881, PCO1810 |

Water, Juice, CSD, Daily chemical products, edible oil, medicine |

|

56 cav |

48mm, 38mm, 30/25, 29/25, PCO1881, PCO1810 |

Water, Juice, CSD, Daily chemical products, edible oil, medicine |

|

72 cav |

38mm, 30/25,29/25, PCO1881, PCO1810 |

Water, Juice, CSD, Daily chemical products, medicine |

|

96 cav |

38mm, 30/25, 29/25, PCO1881, PCO1810 |

Water, Juice, CSD, Daily chemical products, medicine |

|

112 cav |

30/25, 29/25, PCO1881, PCO1810 |

Water, Juice, CSD, Daily chemical products, edible oil, medicine |

|

128 cav |

30/25, 29/25, PCO1881, PCO1810 |

Water, Juice, CSD, Daily chemical products, edible oil, medicine |

|

144 cav |

30/25, 29/25, PCO1881, PCO1810 |

Water, Juice, CSD, Daily chemical products, edible oil, medicine |

|

176 cav |

30/25, 29/25, PCO1881, PCO1810 |

Water, Juice, CSD, Daily chemical products, edible oil, medicine |

Mold plate

All mold plate parts are processed by 4Cr13 die steel. The surface hardness of the plate is high, more than 32 degrees HRC, which can effectively reduce the corrosion of the mold surface and slight bumps, and ensure the efficiency of the mold.

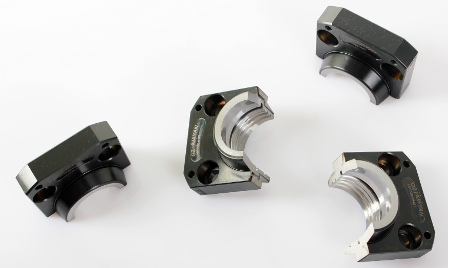

The structure of mold parts

1. The core mold parts are made from S136 high-strength stainless steel imported from Sweden. After processing, the hardness up to HRC52-54 degrees, ensuring the mold lifespan.

2. The core adopts taper lock design, easy injection molding and air exhausting, ensure no short shot;

3. The two taper lock design of neckring, precise positioning, more durable, can withstand high pressure injection;

4. The water channel of cavity adopts a spiral independent rapid circulation structure, to ensure fast cycle time;

5.Improved parts process, all tapers and surfaces are machined precisely to ensure longer life of parts.

Neckring Coating

The neckring can do the wear-resistant coating treatment. The hardness can reach HRC70°, and it has excellent anti-wear feature, can further improve the life of the mold. The lifespan of the neckring can be extended to 30 million shots.

Hot Runner

The hot mold adopts a 2-plate combination type, and the hot runner is directly embedded in the bottom plate milled by the machining center, the hot mold sealing performance and strength are better, and the plate deformation amount is small.

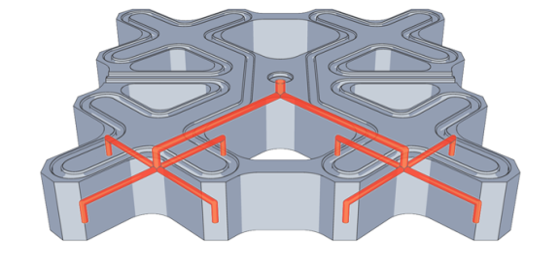

Hot Runner Manifold

|

|

Benefits of Huayan Hot Runner Manifold:

1. The hot runner plate is designed in the best natural balance, each design of the hot runner is subject to professional software analysis. results in an optimal thermal balance layout.

2. The cross-sectional size of the runner aperture is determined by different products, We will provide the best injection shear force for different applications to reduce pressure drop and get the best molding cycle.

3. More uniform hot runner plate temperature, temperature difference between melt channels ≤3°C, the consistency of product molding is good.

4. Has a wider process window and lower AA value and IV drop.

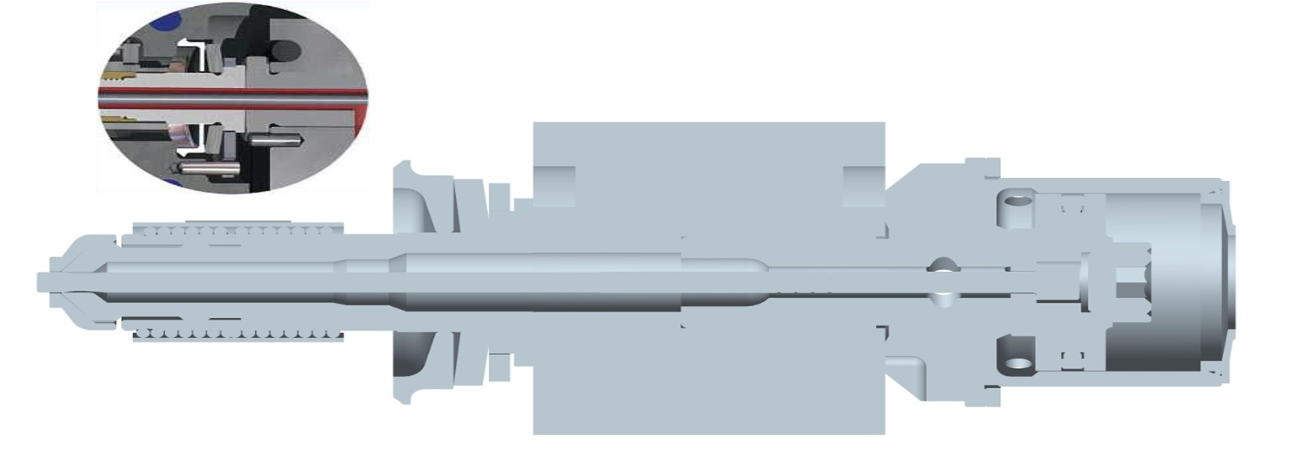

Hot Runner Piston Cylinder

Hot Runner Core Accessories

Hot Runner Sealing Structure

Adopting advanced and unique elastic flow channel sealing technology, the nozzle holder can be close to the surface of the hot runner plate regardless of the state, ensuring that the glue will not leak for a long time;

The back of the cylinder is also elastically sealed, and the cylinder seal is not affected by the cold and heat.

Hot Runner Nozzle

1. The internal structure of the nozzle has been professionally improved, and there is no drift phenomenon during injection molding to ensure balanced injection.

2. The thermal curve of the nozzle is more precise. Under normal production conditions, the temperature of our temperature control components can be precisely controlled.

3. It is within ± 0.5 °C to ensure stable process and product quality.