Item NO.:

Eone-230Product Origin:

ChinaThe Eone series electric servo type PET preform injection molding system is a high-quality energy-saving model suitable for small batches production. On the basis of maintaining economy and applicability, cycle time, mechanical strength, product quality, and operating costs of the equipment have been carefully adjusted with series optimization design. It can provide customers with better economical operating costs and produce high-quality preforms. This series of models has high flexibility and can meet the requirements of different production volumes.

Compared with ordinary injection molding machines, the operating cost advantages of electric Econ are mainly reflected as follows:

1. The fully automatic system is highly intelligent. One machine is equivalent to the output of two ordinary machines, and the labor cost is only half of that of ordinary injection molding machines;

2. Low energy consumption for production, more than 35% energy saving than ordinary servo injection molding machines, more than 50% energy saving than traditional non-servo injection molding machines, and only 0.4KWH per kilogram of preform is produced;

3. The finished product rate is high. Ordinary injection molding machines have a reject rate of 1.5%, while the Econ preform injection system has a product pass rate of 99.7%;

4. Econ has excellent plasticizing effect and excellent color mixing performance, and is a good choice for producing high-quality preforms.

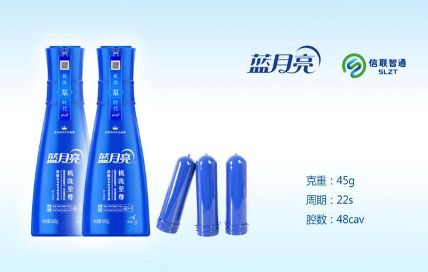

The production cost of each preform produced by the Econ series is much lower than that of ordinary machines. Taking the production of 15 grams of water embryos with 48 cavities as an example, the application of Econ (48/72) cavity preform injection system is compared with that of ordinary machines. The production cost can be saved by 0.009 yuan. Calculated on the basis that 143 million preforms can be produced in 320 days a year, it can generate at least 1.28 million yuan in additional income for customers every year.

PRODUCT FEATURES

l Up to 96cav mold.

l With 9s cycle time, up to 25,000 preforms/hr.

l Specially designed clamping unit extends mold user life.

l Independent electrical plasticization unit with servo motor saves energy consumption dramatically.

l Robot with 3-position take-out plate ensures fast & accurate preform pick up as well ass longer post-mold cooling.

CRITICAL PART AND FEATURES

l Rapid and accurate extraction of preform.

l Optimized design to prolong mold service life.

l Multi-threaded screw design improves plasticization quality and efficiency

l Remarkable energy-saving effect of melting, about 40% more energy-saving than traditional hydraulic type.

PARAMETER INFORMATION

| Machine Model | Eone-230 | |||||

| Injection Unit | Screw L/D Ratio | L/D | 25 | 25 | ||

| Screw diameter | mm | 85 | 100 | |||

| Injection Pressure | kgf/cm2 | 997 | 991 | |||

| Machine Size (L*W*H) | mm | 980*360*210 | 1000*430*240 | |||

| Shot Volume (Max) | cm3 | 1872 | 3140 | |||

| Shot Weight | g | 2152.4 | 3611 | |||

| ozs | 76.1 | 127.6 | ||||

| Clamping Unit | Clamping Force | Ton | 230 | |||

| Clamping Stroke | mm | 550 | ||||

| Mold Thickness | mm | 500~850 | ||||

| (min/max) | ||||||

| Tie-bar Spacing (W*H) | mm | 660*720 | ||||

| Ejector Stroke | mm | 200 | ||||

| Ejector Force | Ton | 8+19.9 | ||||

| No.of Ejector Pins | Piece | 13 | ||||

| System Pressure(max.) | kg/cm2 | 160 | ||||

| Preform Mold | Cavitation | cavitation | 48/72 | |||

| Preform Length (Max) | mm | 200 | ||||

| Hot runner | Pneumatic Valve-gated hot runner mold | |||||

| Electrical System | Pump Motor Power | KW | 78+0.95 | 78+0.95 | ||

| Robot Power | KW | 5.8+3.4 | 5.8+3.4 | |||

| Mold heating | KW | 42 | 50 | 42 | 50 | |

| Machine Heating | KW | 40 | 65 | |||

| Plasticizing motor power | KW | 54 | 78 | |||

| Robot | preform cooling mechanism | Piece | 48*3 | 72*2 | 48*3 | 72*2 |

| General Requirements | AC Power | V | 380 | |||

| (3 phase 4 line) | KW | 227.2 | 235.2 | 276.2 | 284 | |

| Chilling Water | ℃ | 5~15 | 5~15 | |||

| Mpa | 0.8 | 0.8 | ||||

| L/min | 600 | 900 | 600 | 900 | ||

| Cooling Water | ℃ | <25 | <25 | |||

| Mpa | 0.3 | 0.3 | ||||

| L/min | 400 | 400 | ||||

SOLUTION

HUAYAN SERVICES

Huayan adheres to the spirit of professional service, and provides customers with high-quality value-added services, and strives to build a solid partnership. Committed value-added services include the following:

l Every year, Huayan will organize personnel to come to the factory for free training according to the needs of customers. The training will be implemented in stages according to customer needs to ensure that sufficient technical personnel are trained for customers.

l 7x24 hours of expert service, remote diagnosis. Uninterrupted free service telephone support throughout the year. The equipment has a remote connection function, which can realize instant information exchange and remote fault diagnosis. One or two free door-to-door comprehensive services will be provided every year;

l Huayan insists on responding quickly to customer needs and reducing equipment downtime caused by unforeseen failures. If the equipment is down, the spare parts center will respond within 2 hours. If spare parts are in stock, they will arrange delivery within 24 hours. If there is no stock, we will confirm the latest delivery time, and try our best to expedite the production or deployment to meet customer needs.

l During the free inspection period every year, a special inspection report will be provided. Predictive maintenance is a planned evaluation of equipment performance, maintenance or correction to make equipment achieve operational efficiency, reduce high maintenance costs and downtime caused by failures, and reduce production losses.

l Huayan provides customers with excellent refurbishment services. The company has set up a professional mold refurbishment center. We can clean, refurbish and repair molds at different levels according to the use of the mold (combined with the number of running molds and the quality of the preform). In turn, the production downtime of the customer's factory is greatly shortened, and the service life of the mold can be greatly extended to ensure the quality of the product.