Item NO.:

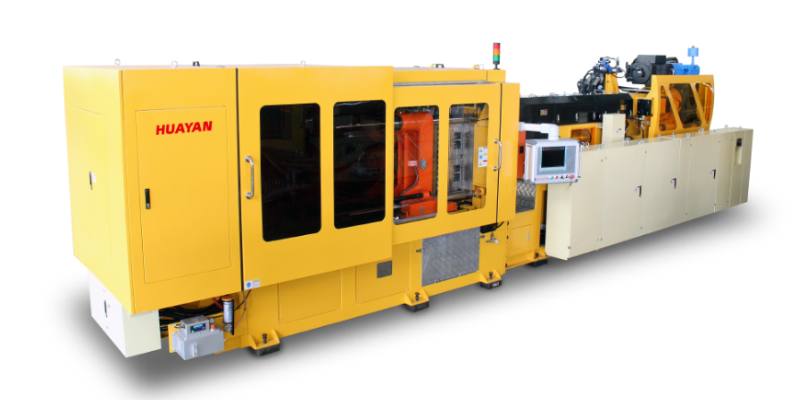

EcoSys-400Product Origin:

ChinaEcoSys series preform injection system is an energy-saving and high-efficiency PET injection molding system developed and designed by Huayan according to market demand. Whether it is hardware configuration, mechanical performance, production efficiency, production energy consumption, etc., it is at the same level as the current world-class equipment, but the price is about half of the imported equipment, which is extremely cost-effective. Its performance characteristics such as energy saving, high efficiency and stability are also widely praised by customers. It has been widely used in the preform production of well-known enterprises such as water, beverages, edible oils, and daily chemical products.

Features of EcoSys series models:

(1) High-strength frame prolongs the service life of the mold;

(2) The highly flexible formwork is compatible with the installation of imported equipment molds;

(3) Full-servo electric plasticizing and melting mechanism, which greatly saves plasticizing energy consumption;

(4) High-performance screw combined with efficient and continuous melting technology, the plasticizing ability is greatly improved;

(5) The multi-cylinder balanced auxiliary enhanced ejection mechanism has greater ejection force and reduces the deformation of the top plate;

CRITICAL PART AND FEATURES

l Rapid and accurate extraction of preform.

l Optimized design to prolong mold service life.

l Multi-threaded screw design improves plasticization quality and efficiency

l Remarkable energy-saving effect of melting, about 40% more energy-saving than traditional hydraulic type.

PARAMETER INFORMATION

| Machine Model | Ecosys-400 | |||||

| Injection Unit | Screw L/D Ratio | L/D | 27.5 | 28.5 | ||

| Screw diameter | mm | 120 | 140 | |||

| Injection Pressure | kgf/cm2 | 1125 | 1091 | |||

| Machine Size (L*W*H) | mm | 13800*4380*2600 | ||||

| Shot Volume (max.) | cm3 | 3956 | 5837 | |||

| Shot Weight | g | 4747.2 | 7004.4 | |||

| ozs | 169 | 248 | ||||

| Clamping Unit | Clamping Force | T | 400 | |||

| Clamping Stroke | mm | 600 | ||||

| Mold Thickness (min./max.) |

mm | 550~1100 | ||||

| Tie-bar Spacing (W*H) | mm | 920*920 | ||||

| Ejector Stroke | mm | 200 | ||||

| Ejector Force | Ton | 14+44.8 | ||||

| Ejector Pins | Piece | 7 | ||||

| System Pressure (max.) | kg/cm2 | 180 | ||||

| Preform Mold | Cavitation (max.) | cavitation | 96 | |||

| Preform Length (max.) | mm | 200 | ||||

| Mold type | Valve-gated hot runner mold | |||||

| Electrical System | Robot Power | KW | 30 | 51.5/57 | ||

| Mold heat | KW | 89 | ||||

| Machine Heat | KW | 108 | 140 | |||

| Motor power | KW | 110+122+2.8 | 110+154+2.8 | |||

| Robot | Multi-position cooling mechanism | Piece | 384 | 512 | ||

| General Requirements | AC Power (3 phase 4 line) |

V | 380 | |||

| KW | 462 | 547.3/552.8 | 221 | |||

| Chilling Water | ℃ | 8~12 | 8~12 | |||

| Mpa | 0.8 | 0.8 | ||||

| L/min | 900 | 900 | 600 | |||

| Cooling Water | ℃ | <25 | <25 | |||

| Mpa | 0.3 | 0.3 | ||||

| L/min | 400 | 400 | ||||

SUCCESSFUL CASE

Huayan EcoSys400 in C'estbon Water Production Line of Ningxiang Xinlian Factory