The equipment is mainly used to detect appearance defects of PET bottle preforms (including sealing mouth gaps, flash; bottle shrinkage, black spots and bubbles, etc.; glue injection port evacuation and drawing). The detection function is modular and can be configured according to customer needs. Suitable for online inspection of bottle preforms of various specifications.

Item NO.:

DP600Product Origin:

ChinaPET Preform Automatic Inspection Machines DP600 is an intelligent visual inspection equipment independently developed by Huayan. It is used to detect whether the infusion product solution contains fibers, hair, mosquitoes, paper scraps, white blocks, black spots, color blocks and other foreign matter. It also has bottle Appearance detection functions such as cap defects, bottom ring defects, bottle defects and filling quantity have the advantages of high detection efficiency and low false detection rate. This product is suitable for the detection of large infusion products in glass bottles and plastic bottles in the pharmaceutical industry.

The equipment is mainly used to detect appearance defects of PET bottle preforms (including sealing mouth gaps, flash; bottle shrinkage, black spots and bubbles, etc.; glue injection port evacuation and drawing). The detection function is modular and can be configured according to customer needs. Suitable for online inspection of bottle preforms of various specifications.

PET bottle preforms are semi-finished products for beverage packaging bottles and inevitably have defects during the production process. Choosing a suitable fully automatic preform visual inspection machine that can replace manual visual inspection has become the consensus of many preform manufacturers.

Bottle preforms currently have problems such as broken support rings, flash, hollows, missing glue, bubbles, damaged bottle mouths, ovals, impurities, etc., which directly or indirectly cause the final product to be unqualified and bring huge losses to the enterprise. How to remove defective bottles before canning is an important issue faced by PET bottle manufacturers.

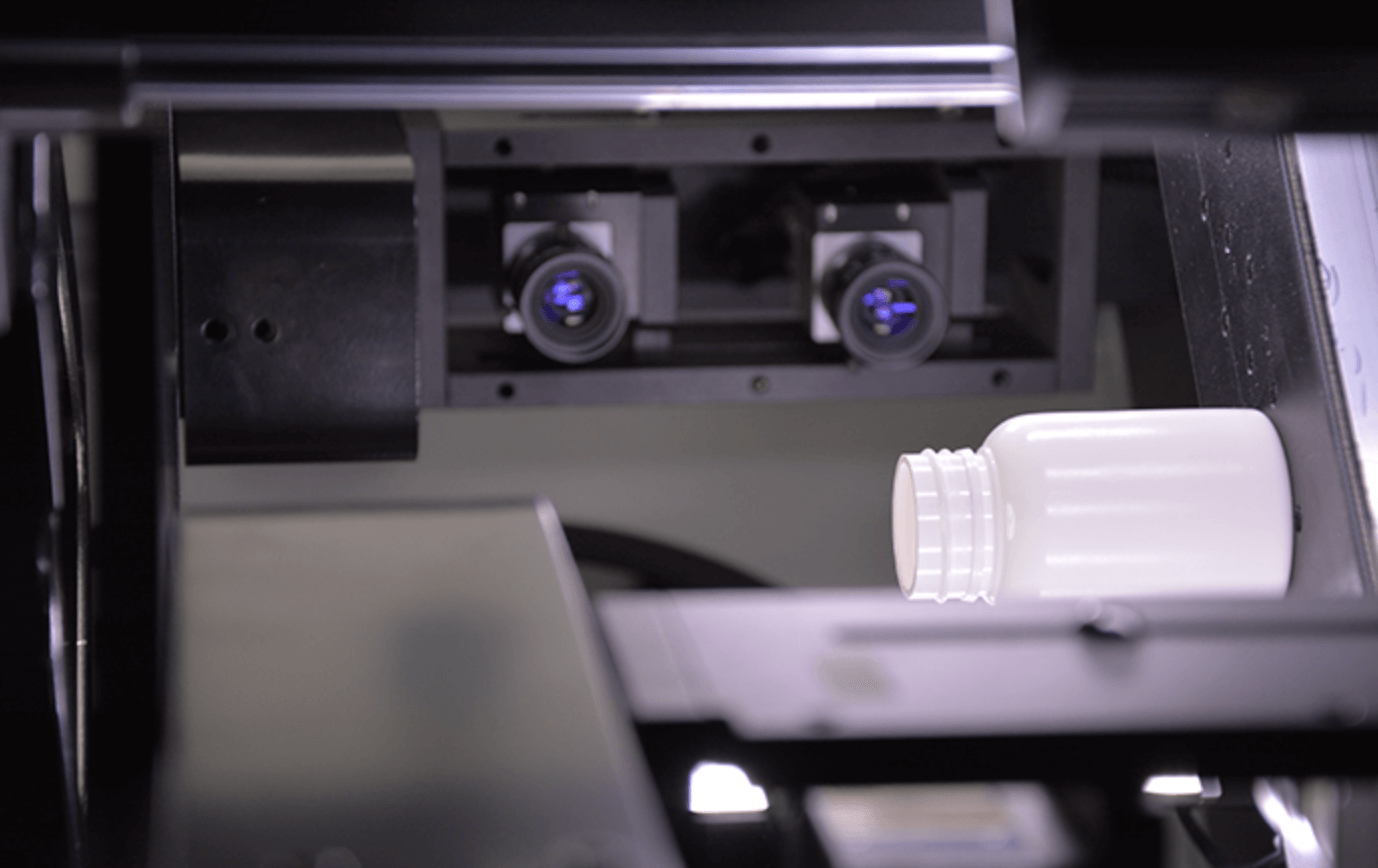

The PET bottle visual inspection machine is a PET bottle preform appearance defect inspection equipment based on machine vision. Compared with the traditional manual light inspection method, this equipment greatly improves the accuracy, reduces inspection time, and reduces production costs. At the same time, the work quality of each process in the production process and the types of defects can be collected and fed back for analysis and management by process control personnel to improve product quality.

The testing machinery can be equipped with multiple cameras according to the actual needs of the user to meet the requirements for detection speed and detection surface. In addition, the PET preform detection machine can also be directly connected to the bottle blowing machine, used in conjunction with the embryo clearing machine, or can be added at the back end of the test Back-end auxiliary equipment such as side leakage machines, balers, and cartoning machines can realize a complete chemical industrial process from feeding, sorting, testing, screening and rejection to packaging.

The PET bottle preform visual inspection machine can detect all kinds of bottle preform appearance problems online around the clock. It is far superior to manual work in terms of speed and accuracy, and is increasingly becoming an emerging intelligent unmanned inspection solution that replaces manual work.

HUAYAN SERVICES

Huayan adheres to the spirit of professional service, and provides customers with high-quality value-added services, and strives to build a solid partnership. Committed value-added services include the following:

l Every year, Huayan will organize personnel to come to the factory for free training according to the needs of customers. The training will be implemented in stages according to customer needs to ensure that sufficient technical personnel are trained for customers.

l 7x24 hours of expert service, remote diagnosis. Uninterrupted free service telephone support throughout the year. The equipment has a remote connection function, which can realize instant information exchange and remote fault diagnosis. One or two free door-to-door comprehensive services will be provided every year;

l Huayan insists on responding quickly to customer needs and reducing equipment downtime caused by unforeseen failures. If the equipment is down, the spare parts center will respond within 2 hours. If spare parts are in stock, they will arrange delivery within 24 hours. If there is no stock, we will confirm the latest delivery time, and try our best to expedite the production or deployment to meet customer needs.

l During the free inspection period every year, a special inspection report will be provided. Predictive maintenance is a planned evaluation of equipment performance, maintenance or correction to make equipment achieve operational efficiency, reduce high maintenance costs and downtime caused by failures, and reduce production losses.

l Huayan provides customers with excellent refurbishment services. The company has set up a professional mold refurbishment center. We can clean, refurbish and repair molds at different levels according to the use of the mold (combined with the number of running molds and the quality of the preform). In turn, the production downtime of the customer's factory is greatly shortened, and the service life of the mold can be greatly extended to ensure the quality of the product.